Wire Cut Cookie Machines

Soft cookie dough pieces are formed using a wire cut machine. Dough is forced through a filler block and die cup arrangement by a pair of contra-rotating rolls. As dough extrudes from the base of the die cups, a wire (or blade) cuts a disc shape that transfers to the outfeed conveyor. To promote efficient transfer, a band raise mechanism lifts the outfeed conveyor and reduces the die cup to band clearance. Passages are machined into the filler block to direct dough to the die cups. They help to create equal pressure at the base of each die cup and give good weight distribution across the machine. Typically, product sizes of 20mm to 80mm diameter can be produced. Sizes of less than 20mm diameter require extra features to generate sufficient pressure and overcome friction. The standard machine can be adapted to operate as a Rout Press extruder, a deposit machine or a co-extrusion machine for filled bars. The deposit machine can include swirl (or rotating) nozzles to give an attractive finish to soft dough products. Technical Specifications Standard Stainless steel grooved rolls Filler block for improved side to side weights 150 cuts per minute Stainless steel “low head” hopper Outfeed conveyor Band raise mechanism below die cups Variable roll and wire cut speeds Variable wire cut stroke and wire drop Options PTFE liners for filler block Independent roll drives Higher cut rates depending upon dough piece size Oscillating wire cut Blades for dough with inclusions Over the oven band operation Mobile option with machine mounted control panel Rout press and deposit options Co-extrusion and filled bar...

read moreRotary Moulder

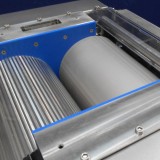

Soft dough biscuits with high combined sugar and fat content are normally rotary moulded. Dough is forced into impressions engraved around a die roll. Excess dough is trimmed away by a scraper knife. The key to successful rotary moulding is to form a blanket of dough around the forcing roll. It is normally grooved and castellated to provide maximum adhesion for the dough blanket. Dough pieces are then removed from the impressions by an extraction web backed up by a rubber extraction roller. A spur gear transmission to the die roll allows ease of removal. Once the bearing retaining clamps are released, the die roll can be raised and removed from the machine. The scraper blade can be adjusted for height to obtain the optimum operating conditions. This is an operator function for increased flexibility. Dough should be kibbled before depositing into the nip formed by the die roll and forcing roll. Kibbling assists the dough blanket to form around the forcing roll. Soft dough rotary moulders expand the envelope of products that can be produced by this method of production. Extra features are required especially to support dough in the die roll impressions. Different roll geometry and a special scraper are included to cope with the properties of soft dough. Technical Specifications Standard Dual hardness rubber extraction roller Endless extraction belt for ease of fitting Adjustable height scraper blade Lift-off interlocked stainless steel hopper Spur gear transmission for ease of die roll removal Variable gap flanged forcing roll Variable pressure rubber extraction roll 10.2” (259.1mm) diameter die rolls. Options Variable extraction point from die roll Independent forcing roll drive Automatic web tracking Transfer roller for very small products Positive ejection die roller and stripping wire Split hopper partition for dual dough operation Soft dough machine version Panning discharge version Dough...

read moreRotary Cutter

Extensible (or hard) dough products are normally formed into a sheet before rotary cutting. The process of rotary cutting creates a scrap dough lattice that must be separated from the product before it enters the oven. Also, some products require the addition of text or other surface pattern including docker holes. The Arrow rotary cutter has two stations – one for docking the dough sheet and a second for cutting the dough piece from the sheet. Scrap dough is lifted from the cutter web conveyor by a scrap lift conveyor. The dough pieces continue into the oven for baking. Cutter and docker rolls are fixed and normally do not move. Rubber coated anvil rolls below the cutter web belt move upwards to force the dough sheet against the cutter and docker rolls. At Arrow, anvil rolls are constructed using a dual rubber compound. A softer inner layer of rubber provides some shock absorption during the cutting and docking process. When applying text or a surface pattern to the dough piece, the cutter and docker rolls must align. A roll phasing mechanism is used to maintain alignment. This control is an operator function and adjustments can be made easily and quickly. The cutting and docking pressures can be adjusted to compensate for variations in dough sheet properties. A simple control on the rotary cutter can be used by the operator to achieve the desired pressure setting. Products with inclusions can be difficult to rotary cut. Cutters cannot generate enough pressure to cut through the inclusion without damaging the cutter belt. A webless rotary cutter arrangement can give improved performance and eliminate cutter belt failure. The dough sheet is presented to the rotary cutter on a conveyor belt in the normal way. The dough sheet then passes through the webless cutter section before transferring back to the cutter belt. Technical Specifications Standard Four roll design for cutting and dockering Dual rubber compound anvil rolls Cutter and docker roll phasing mechanism Variable pressure anvil roll raise mechanism Spur gear transmission to ease of roll removal Standard cutter diameters – 130mm to 175mm Options Independent cutter and docker roll transmissions Dual cutter roll operation for multi products Webless rotary cutting system Anti dough sheet wrap system for cutter rolls Dough skinning fans Cutter and docker rolls Combined cutter and dockering...

read moreCombination Dough Sheeter

The Arrow Combination Dough Sheeter utilizes a selection of novel features to guarantee accurate and consistent dough sheet quality. A range of dough types – wheat, potato and corn – can be sheeted for either further reduction by gauge rolls or rotary cut prior to baking / onward processing. A two roll sheeter option can be created by removing the bottom sheeting roller. The design meets daily production demands whilst maintaining ease of operation and sanitation. Innovative Design to create a dough sheet of uniform thickness. The three roll sheeter has a pressure pocket between the rollers to remove voids in the dough sheet. A novel “barb” type scraper supports the dough sheet at the transition between rollers and conveyor in order to maintain dough sheet integrity. The machine can be extended to provide facilities for dough sheet sample cutting or inclusion of reduction rolls or a rotary cutting section. Precise Sheeting is the primary function of the Arrow Combination Sheeter. In three roll configuration, the combination sheeter can produce sheets down to 3mm thickness. Alternatively, the two roll machine can produce a final sheet thickness of 1mm. Conversion between three roll and two roll operation is easy and the machine can be supplied with a conversion kit. The benefits of conversion are the wide range of dough types that can be processed from biscuits to tortillas. Robust Stainless Steel construction is used throughout the sheeter. The height of the machine is designed to give good access without the need for steps. All major assemblies can be removed for sanitation purposes. Roll gaps are fully adjustable. Stops are included on the gap adjustment to prevent rolls coming into contact. Technical Specifications Key Features Stainless steel construction Separate roll and conveyor drives Variable frequency drives on rolls and conveyor Speed cascade on roll and conveyor for ease of operation Mobile design with braked casters Removable hopper for sanitation purposes Forcing roll compression change parts kit Adjustable roller side cheeks to prevent dough leakage from base of hopper Options Independent roll drives Motorized gap adjustment mechanism Chilled rolls Hardened rolls for tough dough types Rotary cutter section can be included Conversion parts can be supplied for Tortilla production Conversion kit for 2 roll sheeter...

read more